Yogurt Starter Culture Tube

The yogurt starter culture tube is a piece of equipment used in yogurt production to inject starter culture (yogurt bacteria) into pre-filled containers of milk using a specialized gun. This ensures precise and hygienic distribution of the culture, which is essential for consistent fermentation and high-quality yogurt production.

Types of Yogurt Starter Culture Dispensing Systems:

-

Starter Culture Tube (Manual):

-

Description:

-

A 30-liter tank with a dispensing outlet at the bottom and a hygienic cleaning lid at the top.

-

Operates using compressed air.

-

Equipped with a regulated air inlet and valve for air supply.

-

Includes a safety valve for system security.

-

-

Process:

-

Milk and starter culture are filled into the tank and mixed.

-

The lid is closed, and the air inlet is opened.

-

Operates at a pressure of approximately 1-2 bar.

-

The compressed air pushes the cultured milk into pre-filled milk containers via a manual gun.

-

-

-

Pump-Based Starter Culture Tube:

-

Description:

-

A 30-liter tank and pump are mounted on a platform.

-

The pump transfers the cultured milk from the tank to the dispensing guns.

-

Manual dosing is performed using the guns.

-

-

Advantages:

-

Does not require compressed air, making it safer and more reliable.

-

Eliminates the risks associated with pressurized systems.

-

-

-

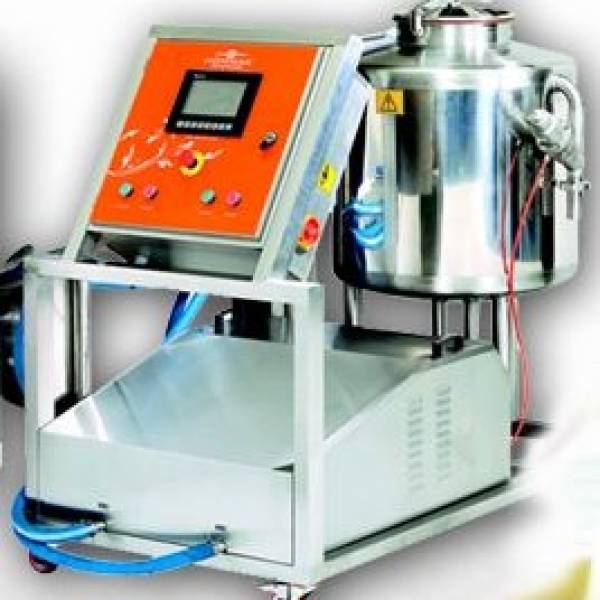

Automatic Starter Culture Dosing Machine:

-

Description:

-

A fully automated system that uses a flow meter to precisely dose cultured milk in desired quantities.

-

Available in 2-4 operator configurations.

-

Ensures accurate and consistent dosing of starter culture.

-

-

Importance:

-

Critical for achieving the desired texture, taste, and acidity level of yogurt.

-

Ensures the correct amount of starter culture is added, which is vital for product quality.

-

-

Key Features of the Starter Culture Dosing Tank:

-

Manual Dosing System:

-

The operator ensures the correct amount of starter culture is added.

-

Critical for achieving the desired texture, taste, and acidity level of yogurt.

-

-

Hygienic Design:

-

Made from food-grade stainless steel (typically AISI 304 or 316).

-

Features hygienic connections and easy-to-clean surfaces.

-

-

Capacity:

-

Typically ranges between 20-40 liters.

-

-

Mobility:

-

Equipped with wheels for easy movement to desired locations.

-

Applications:

-

Industrial yogurt production facilities.

-

Cheese and other fermented dairy product production.

-

Small-scale milk processing plants.

Key Considerations:

-

Cleaning and Sterilization: Critical for product quality and safety.

-

Regular Calibration: The dosing system must be regularly calibrated to ensure accuracy.

The yogurt starter culture dosing tank is a vital piece of equipment in industrial yogurt production, enhancing efficiency and product quality. Proper selection and use optimize the production process and reduce costs.

Related Keywords:

-

Starter culture dosing machine,

-

Starter culture tube,

-

Yogurt starter culture tube,

-

Pump-based starter culture tube,

-

Pump-based starter culture tank,

-

Starter culture preparation and dosing tank,

-

Starter culture dosing tank,

-

Starter culture dosing tube,

-

Pump-based starter culture dosing.