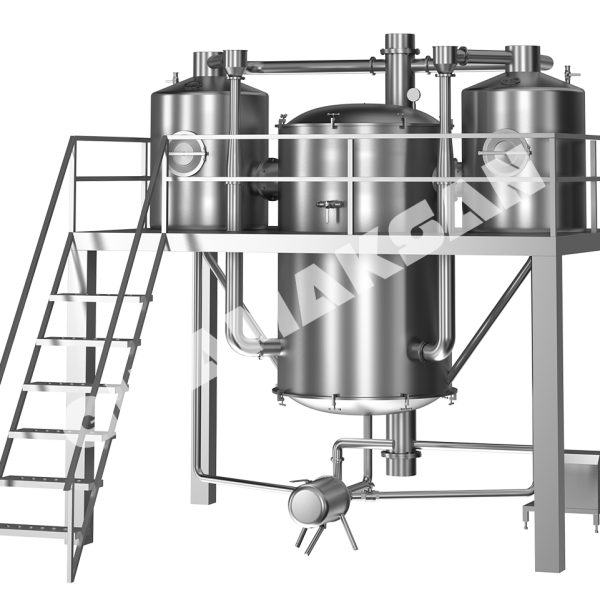

Vacuum Evaporator

The vacuum evaporator is a state-of-the-art equipment used in the dairy industry to concentrate milk, remove water, and preserve its nutritional value. This system plays a crucial role in processes such as milk powder production, whey concentration, and the processing of other dairy products. Vacuum evaporators operate at low temperatures, ensuring the preservation of vitamins and minerals in milk while also improving energy efficiency and reducing operational costs.

Working Principle of a Vacuum Evaporator:

-

Vacuum Environment:

-

The system operates under low pressure, which lowers the boiling point of milk, allowing it to evaporate at lower temperatures.

-

Low temperatures help preserve the nutritional value of the milk.

-

-

Heating and Evaporation:

-

The milk is heated and evaporated inside the evaporator. During this process, the water in the milk evaporates, and the milk becomes concentrated.

-

In multi-stage systems, steam is reused to achieve energy efficiency.

-

-

Condensation:

-

The evaporated water is condensed back into liquid form in the condenser unit and removed from the system.

-

-

Concentrated Product Output:

-

At the end of the process, the milk reaches the desired dry matter content and is stored in a concentrated form.

-

Features of the Vacuum Evaporator:

-

Hygienic Design:

-

Made from stainless steel (304 or 316 grade).

-

Designed in compliance with food safety standards.

-

-

Energy Efficiency:

-

Steam is reused through multi-stage systems or venturi effects, ensuring energy savings.

-

-

Automation System:

-

Modern vacuum evaporators are equipped with automatic control systems, enabling precise management of operations.

-

-

Multi-Stage System:

-

Operates with multiple evaporator stages for higher efficiency.

-

-

Wide Capacity Options:

-

Available in models suitable for small-scale operations to large-scale factories.

-

Applications of the Vacuum Evaporator:

-

Concentrated (Condensed) Milk Production: Removing water from milk to produce milk with a high dry matter content.

-

Yogurt Production: Yogurt made from condensed milk has a firmer texture.

-

Milk Powder Production: Removing water from milk to turn it into powder.

-

Whey Concentration: Processing whey produced during cheese production.

-

Fruit Juice and Other Foods: Concentrating fruit juices, syrups, and other foods outside the dairy industry.

Advantages of the Vacuum Evaporator:

-

Preserves Nutritional Value: Operates at low temperatures to retain the vitamins and minerals in milk.

-

Removes Gas and Odors: Eliminates unwanted odors and gases from the milk.

-

Energy Savings: Ensures energy efficiency through multi-stage systems.

-

High Efficiency: Quickly and effectively removes water from milk.

-

Hygienic Operation: Ensures food safety with its stainless steel structure and easy-to-clean design.

-

Long-Lasting: Made from high-quality materials, ensuring trouble-free use for many years.

SEO-Friendly Keywords:

-

Vacuum evaporator

-

Dairy industry evaporator

-

Milk concentration system

-

Milk powder production equipment

-

Whey evaporator

-

Stainless steel evaporator

-

Multi-stage evaporator

-

Energy-efficient evaporator

-

Milk processing equipment

-

Food industry evaporator

The Vacuum Evaporator is a piece of equipment that enhances the efficiency of production processes in the dairy industry while preserving product quality. This system plays a significant role in processing products such as milk powder and whey. For businesses operating in the dairy sector, the vacuum evaporator is a strategic investment that increases production capacity and reduces costs.

Since the machine operates under vacuum, the boiling point is lowered, ensuring that minerals in the product are not damaged. It allows for rapid evaporation of water and consumes less energy.

Capacities: 1,000, 2,000, 3,000, 4,000, 5,000, 7,500, 10,000, 15,000 liters.