Milk Cooling Tank

In the dairy industry, a milk cooling tank is an essential piece of equipment used to rapidly cool raw milk, preserving its freshness and quality. If raw milk is not cooled quickly after milking, the growth of microorganisms accelerates, increasing the risk of spoilage. Milk cooling tanks ensure that the milk is rapidly cooled to the ideal storage temperature of 4°C, maintaining its quality and extending its shelf life. These tanks are widely used in dairies, milk collection centers, and milk processing facilities.

The stainless steel milk cooling tanks produced by our company are designed to cool milk from 35°C to 4°C under ambient conditions of 32°C, providing the ability to cool half the tank's volume in less than 3-3.5 hours. The reason for cooling half the volume is that, in the case of 2-milking tanks, morning and evening milk are added to the tank at different times. Stainless steel is commonly referred to as "chrome" among the public. For this reason, these tanks are also known as chrome cooling tanks or stainless steel cooling tanks.

Features of the Milk Cooling Tank:

-

Hygienic Design:

-

Made from stainless steel (304 or 316 grade).

-

Easy to clean and sterilize.

-

Designed in compliance with food safety standards.

-

-

Cooling System:

-

Rapid cooling is achieved through a cooling jacket (double-walled structure) surrounding the tank.

-

Cooling is performed using compressor-based or ice water systems.

-

-

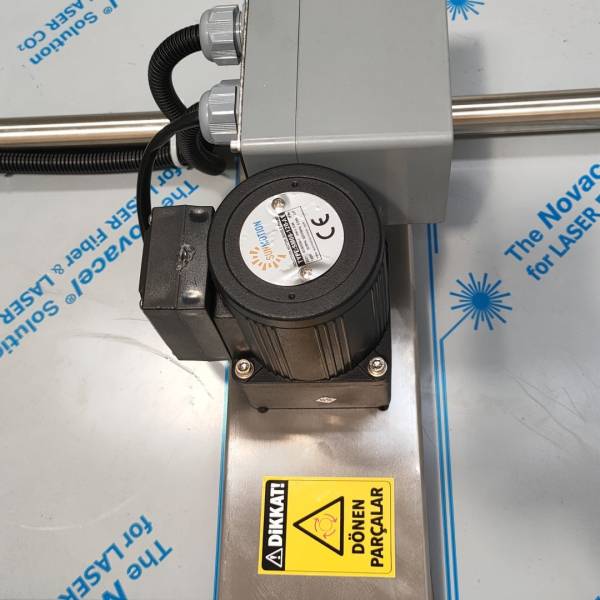

Mixing System:

-

The tank is equipped with a mixer or agitator that ensures homogeneous cooling of the milk. The agitator operates intermittently at set intervals.

-

This prevents clumping or stratification of the milk.

-

-

Capacity Options:

-

Milk cooling tanks are produced in various capacities, designed to meet the needs of small dairies to large milk collection centers.

-

-

Temperature Control:

-

Automatic temperature control systems ensure the milk is maintained at the ideal temperature.

-

-

Insulation:

-

The tank is surrounded by thick insulation material, making the cooling process more efficient and saving energy.

-

Options:

-

Tanks with capacities ranging from 125 to 2000 liters feature a fully openable top lid for manual cleaning.

-

Tanks with capacities above 3000 liters are equipped with an automatic cleaning system (CIP).

-

Load cell units for weighing are available as an optional feature.

Applications of Milk Cooling Tanks:

-

Dairies: Rapid cooling of raw milk after milking.

-

Milk Collection Centers: Storage and cooling of collected milk.

-

Milk Processing Plants: Preserving the freshness of milk before processing.

-

Farms: Cooling milk on livestock farms (both large and small ruminants).

Advantages of Milk Cooling Tanks:

-

Preserves Milk Quality: Rapid cooling of milk prevents the growth of microorganisms and enhances quality.

-

Extends Shelf Life: Cooling extends the spoilage time of milk, maintaining its freshness.

-

Hygienic Operation: The stainless steel construction and easy-to-clean design ensure food safety.

-

Energy Efficiency: The insulated structure and modern cooling systems provide energy savings.

-

Ease of Use: Automatic temperature control and mixing systems make it practical to operate.

-

Long-Lasting: Made from high-quality materials, ensuring trouble-free use for many years.

-

Milk cooling tank

-

Stainless steel milk tank

-

Double-walled milk cooler

-

Milk storage tank

-

Hygienic milk cooling

-

Milk collection center tank

-

Industrial milk cooler

-

Preserving milk quality

-

Extending milk shelf life

The Milk Cooling Tank is an essential piece of equipment in the dairy industry, designed to preserve the freshness and quality of milk. These tanks are indispensable investments, particularly for dairies and milk collection centers where raw milk needs to be rapidly cooled. Milk cooling tanks are a modern solution that enhances product quality while improving the efficiency of operations.