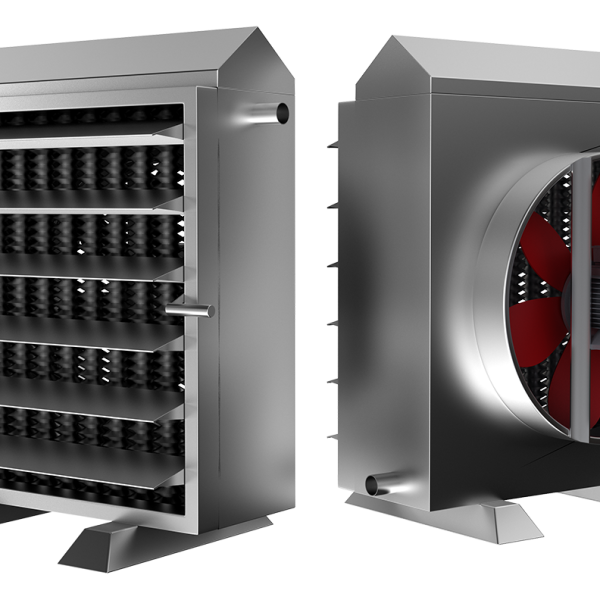

Incubation Chamber Heating Unit

The incubation chamber heating unit is a specialized piece of equipment used in the production of fermented dairy products such as yogurt, cheese, and kefir. It ensures that the environment is maintained at a specific temperature, which is critical for the incubation (fermentation) process. During incubation, microorganisms (e.g., lactic acid bacteria) require optimal temperature conditions to function effectively. The heating unit provides precise and automated temperature control, ensuring consistent and high-quality fermentation.

Key Features of the Incubation Chamber Heating Unit:

-

Heating Elements:

-

Heating is provided using electric resistors, water jackets, or steam systems.

-

Equipped with fans or air circulation systems to ensure uniform heat distribution.

-

-

Hygienic Design:

-

Made from food-grade stainless steel (AISI 304 or 316) suitable for food production.

-

Features easy-to-clean and disinfect surfaces to maintain hygiene standards.

-

These features ensure that the incubation chamber heating unit provides precise temperature control, uniform heat distribution, and compliance with food safety regulations, making it an essential tool for fermented dairy production.

Working Principle of the Incubation Chamber Heating Fan:

-

Product Placement:

-

Products (e.g., fermented milk) are placed inside the incubation chamber and brought to the desired temperature.

-

-

Temperature Control:

-

Heating elements and temperature sensors continuously monitor and regulate the chamber's temperature.

-

-

Air Circulation:

-

If necessary, the heating fan ensures homogeneous temperature distribution through air circulation.

-

-

Completion of Incubation:

-

After the set incubation period, the process is completed, and the product is moved to the cooling or packaging stage.

-

This system ensures precise temperature control and uniform heat distribution, which are critical for successful fermentation and high-quality product outcomes.

Applications:

-

Yogurt production,

-

Cheese production,

-

Kefir and other fermented dairy products,

-

Microbiological laboratories (microorganism culture cultivation),

-

Biotechnology and pharmaceutical industries.

Advantages of the Heating Fan:

-

Precise Temperature Control: Enhances product quality.

-

Energy Efficiency: Provides energy savings due to effective insulation.

-

Automation: Minimizes human error and increases process efficiency.

-

Hygiene: Complies with food safety standards through its hygienic design.

The incubation chamber heating fan is a versatile and efficient solution for maintaining optimal temperature conditions in various industries, ensuring high-quality and consistent results.

Key Considerations:

-

Regular Calibration: Temperature sensors must be regularly calibrated to ensure accuracy.

-

Cleaning and Disinfection: Proper cleaning and disinfection of the incubation chamber are critical for product quality and safety.

-

Energy Consumption: Energy usage should be carefully monitored, especially in large-scale systems.

The incubation chamber heating unit is an indispensable piece of equipment for ensuring consistency and quality in the production of fermented products. Proper selection and use optimize the production process and reduce costs.

Summary:

-

Ensures precise temperature control for optimal fermentation.

-

Enhances product quality and safety through hygienic design.

-

Improves efficiency and reduces operational costs through automation and energy efficiency.

By addressing these considerations, businesses can maximize the benefits of the incubation chamber heating unit, ensuring high-quality and consistent production of fermented dairy and other products.