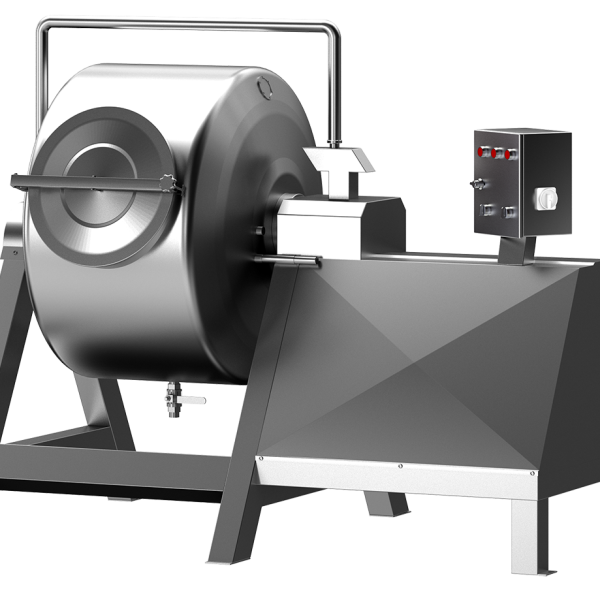

Butter Churn Machine

The butter churn machine is a specialized piece of equipment in the dairy industry that transforms cream into butter through shaking. Combining traditional butter-making methods with modern technology, these machines increase efficiency while ensuring production is carried out under hygienic conditions. Here are detailed insights into the features, working principle, and advantages of the butter churn machine.

What is a Butter Churn Machine?

A butter churn machine is a piece of equipment that allows the separation of fat and the production of butter by mechanically churning cream. These machines are produced in various capacities suitable for both small-scale businesses and industrial facilities.

Features of the Butter Churn Machine

-

Hygienic Design:

-

Made of food-grade stainless steel (AISI 304 or 316).

-

Easy-to-clean and disinfect surfaces.

-

Hygienic connections and seals.

-

-

Mechanical Churning System:

-

Allows the separation of fat by churning cream or yogurt.

-

Can operate with different speed settings.

-

-

Capacity:

-

Models with capacities ranging from 10 to 100 liters for small-scale businesses.

-

Models with capacities from 250 to 2,000 liters and above for industrial facilities.

-

Working Principle of the Butter Churn Machine

-

Loading Cream or Yogurt: Pasteurized cream or yogurt is loaded into the churn machine.

-

Churning Process: The machine mechanically churns the cream. During this process, fat globules come together, and butter separates from buttermilk (fat-free milk).

-

Separation: The fat and buttermilk are separated within the machine.

-

Butter Collection: The butter is collected from the machine and prepared for further processing.

-

Buttermilk Drainage: The buttermilk is drained into a separate tank.

Advantages of the Butter Churn Machine

-

Hygienic Production: Thanks to its stainless steel structure, it enables production under hygienic conditions.

-

High Efficiency: Provides faster and more efficient butter production compared to traditional methods.

-

Energy Efficiency: Reduces operating costs with low energy consumption.

Usage Areas of the Butter Churn Machine

-

Butter Production: Production of butter using pasteurized cream.

-

Dairy Processing Plants: Industrial-scale butter production.

-

Small-Scale Businesses: Suitable models for farms and dairies.

-

Food Processing Facilities: Production of products that use butter.

Why Should You Use a Butter Churn Machine?

-

Combines the traditional taste of butter with modern technology.

-

Ensures high-quality butter production under hygienic conditions.

-

Increases the efficiency and profitability of your business.

-

Reduces operating costs through energy savings.

The butter churn machine is an indispensable piece of equipment in the dairy sector, simplifying and standardizing butter production. With models suitable for both small-scale businesses and industrial facilities, it optimizes your butter production processes, enabling you to obtain high-quality and hygienic products. By choosing a butter churn machine that meets your business needs, you can gain a competitive advantage and offer the best products to your customers.

Keywords:

Butter churn machine, open butter churn, butter kneading machine, dairy sector equipment, butter production machine, hygienic butter production, cream churn machine, industrial butter production, milk processing technology, food production equipment, butter making machine, dairy farm equipment.